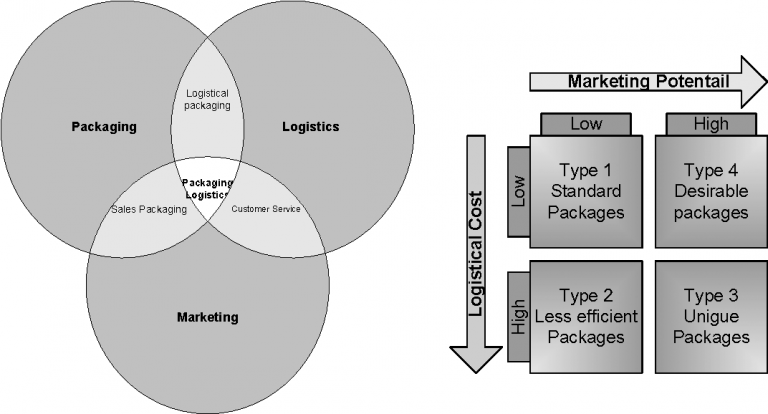

Packaging has a significant impact on the efficiency and effectiveness of retail supply chains, where improvements can be achieved through the adaptation and development of the concept of packaging logistics. In order to enable these improvements, models are needed that facilitate valuations along the supply chain and show the activities involved in the packaging logistics process.

The knowledge and awareness of the importance and potential of the packaging logistics activities along the supply chain are low.

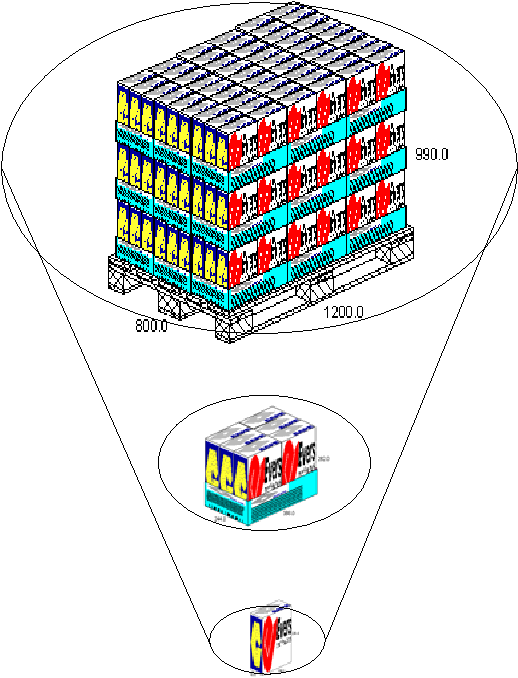

Packaging is a coordinated system of preparing goods for safe, secure, efficient and effective handling, transport, distribution, storage, retailing, consumption and recovery, reuse or disposal combined with maximizing consumer value, sales and hence profit .

Packaging also affects supply chain effectiveness because it represents an interface between the supply chain and its main customer: the end user and enables the chain’s primary task i.e. serving end consumers, to be accomplished. This is especially evident in the FMCG (Fast Moving Consumer Goods) supply chain

There is a need for identifying cost drivers related to the packaging activities in the logistical system. The industry tends to demand tools that show, in a cause-effect fashion, the relationship between packaging properties and tangible logistical service and cost parameters.

Even if we consider the logistical packaging perspective, then we would still need to develop methods and models that can show the influence of packaging on the traditional logistics system.

The evaluation of the packaging system also requires the existence of well-defined requirement measures or factors that would be used in a suggested packaging logistics performance model.

A better understanding of the complexity of packaging logistics and providing new packaging concepts and solutions that facilitate smoother handling throughout the whole supply chain are demanded. In order to develop such concepts, we need to implement proper tools, methods and techniques at an early stage in the process of product development that secure the consideration of packaging logistical issues along the whole supply chain.